- +254100188117

- info@manwelltech.com

- Mon - Sat 8:00 - 17:30, Sunday - CLOSED

Measurement of process parameters is the first step towards controlling a process. Instrumentation helps in tracking material movement, measuring losses and establishing efficiencies of equipment. We assess the industry’s needs in terms of process parameter measurement and select the best instruments for the job. We also advise on the required instruments given the operators’ needs and/or process control philosophy. We deal with all sorts of instruments from basic ones such as thermocouples for measurement and pressure switches to complex ones such as moisture analyzers for product moisture measurement or slurry density meters

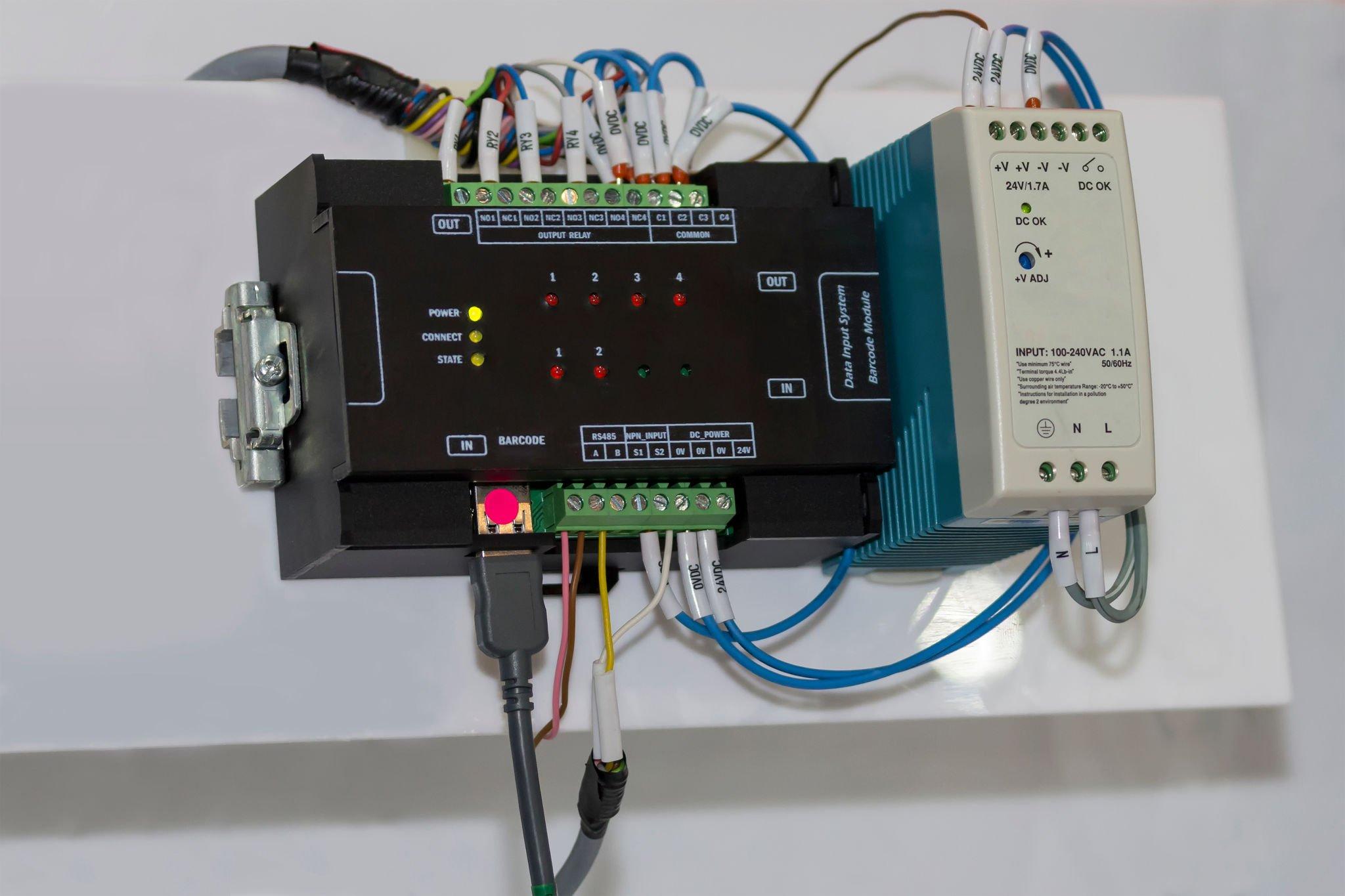

We deploy robust Programmable Logic Controllers(PLCs) that can withstand the harsh industrial environment. We design PLC programs that can automate routine tasks in a fast and efficient manner. Using special functions, we are also able to turn most operations into fully automated, self-adjusting the parameters to track the set point. We are not limited by the brand since we can use Allen Bradley, Siemens, Schneider, Delta and many more.

We also design and build Human Machine Interface(HMIs) that communicate with the small PLCs and enable the machine operator to interact with the PLCs especially for stand-alone machines. We deal with HMIs from different OEMs with different capabilities such web servers and VNC access.

In our portfolio, we also design and build Supervisory Control and Data Acquisition (SCADA) systems. Our SCADA systems have the basic functionalities of graphical representation of various equipment/plants, operation such as use of start/stop buttons, Alarms and Alerting, trending of process parameters and data logging. We build both computer based and web deployable SCADA systems that can be accessible via mobile devices such as laptops, tablets and mobile phones.

We offer solutions for remote connectivity that enable monitoring and/or control of machinery, located in a far from the main plant, in a secure manner through the Machine to Machine(M2M) platform. The exact platform selected depends on, among others, the number of equipment involved, the distance between the various equipment, the existing network strength and topography of the area.

We also offer Mobile View version of the SCADA system that enables launching and running on mobile devices. These version is not limited by the device’ geographical location and hence selected users increased plant visibility