- +254100188117

- info@manwelltech.com

- Mon - Sat 8:00 - 17:30, Sunday - CLOSED

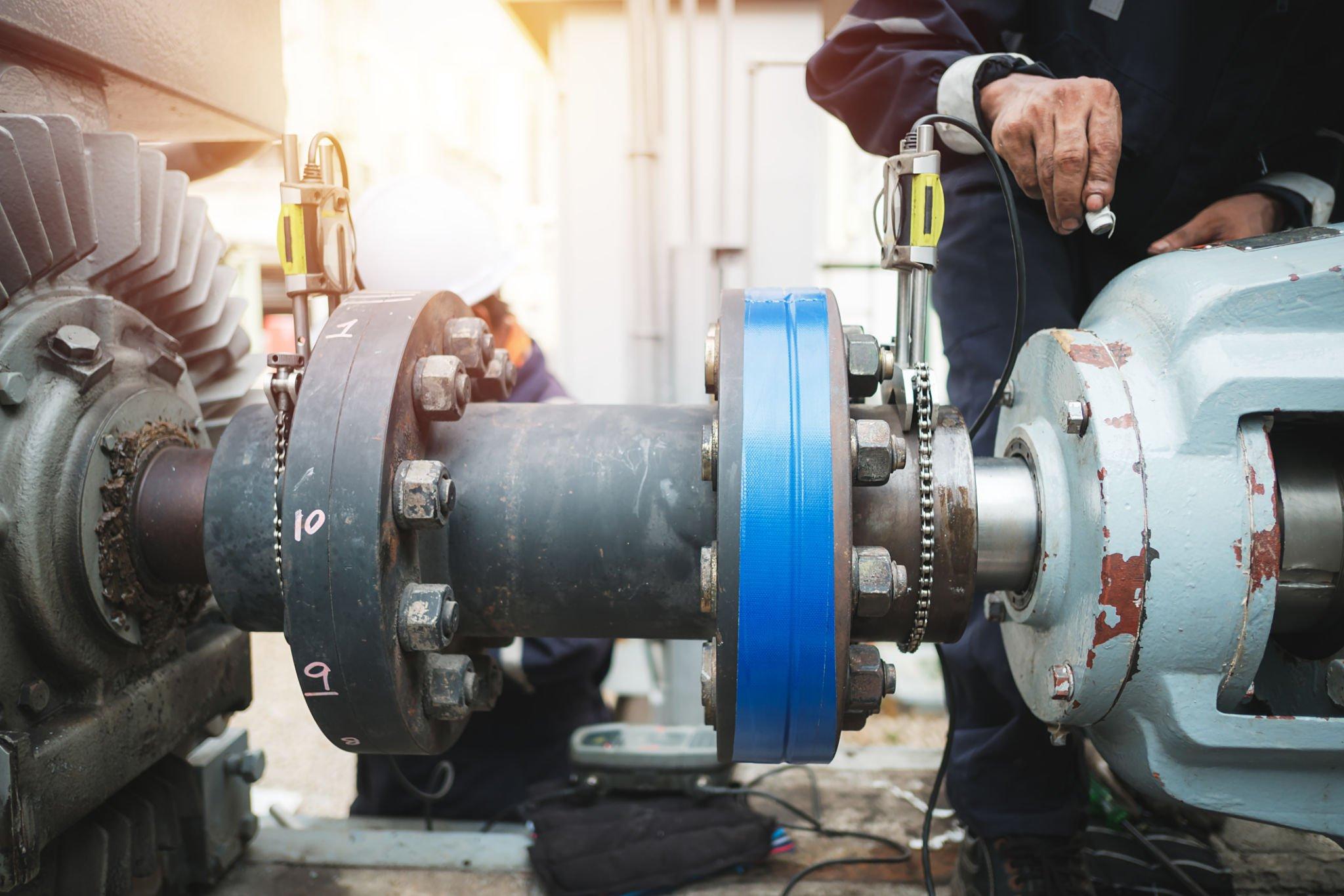

We offer vibration analysis as service for equipment such as gearboxes, motors, pumps and fans. The process involves taking measurements and interpretation of the results. We also help in installation of online vibration monitoring instruments.

Many imminent breakdowns can be picked by well conducted infrared thermography. From monitoring the electrical and mechanical condition of motors to the state of components in substations, from picking impending electrical fires in panels to monitoring deteriorating refractory insulation, you can rely on our team of experts to unearth any underlying problems.

Rotating machines that are out of balance run with high vibrations, noise and heat leading to performance problems. Our teams have wide experience in balancing many machines in a systematic and timely manner. Properly balanced machines will run with minimal vibrations leading to longer machine lifespan.

This is a technique that helps in determining the induction motor’s operating condition without disturbing production. In other words, it senses an electrical signal that has current components and identifies the faults in the initial stage. It can detect bearing faults, broken rotor bars and air gap eccentricity problems in a safe and non-intrusive manner. Other faults it can detect include loose foundation, unbalance/misalignment/coupling, transmission faults, stator/insulation faults.

This is a technique that helps in determining the induction motor’s operating condition without disturbing production. In other words, it senses an electrical signal that has current components and identifies the faults in the initial stage. It can detect bearing faults, broken rotor bars and air gap eccentricity problems in a safe and non-intrusive manner. Other faults it can detect include loose foundation, unbalance/misalignment/coupling, transmission faults, stator/insulation faults.

Transformers are expensive and critical equipment supplying power to many industries. We have systems for measuring important transformer parameters such as transformer oil level, transformer winding and oil temperatures and also the state of the bushings.

The use of Dissolved Gas Analysis (DGA) as a method for determining the types of pending or occurring faults within power transformers has been in practice for many years. It has been proven that the generation of certain gases within a transformer is an excellent indicator that a failure is pending. DGA techniques have become so sensitive and accurate at measuring these gases that the entire scheme has become standard practice as part of the normal maintenance for many electric power utility companies.

We help our customers by sampling, measuring of the gases, interpretation of the results and make recommendations on the best course of actions to take.

Industries have expensive equipment whose condition needs to be monitored round the clock. We provide asset owners with unparalleled confidence and valuable tools to ensure plant operation remains optimized. We champion that condition monitoring shouldn’t be a routine, time based exercise but rather real time activity. We build online and real time condition monitoring systems that are linked to our SCADA systems. Important parameters that tell equipment health such as vibrations, temperature and pressure are picked and sent to the SCADA system and appropriate alarms, trends and data logging takes place. We use highly specialized sensors that can tell the story when it comes to matters equipment health. For instance, our vibration sensors and accelerometers can pick bearing failure before it happens.